Mini Frac Test ServicesFor Civil Engineering

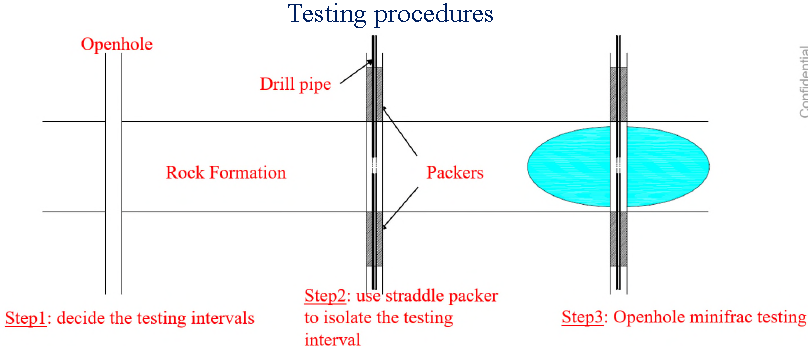

Open Hole Mini Frac Testing

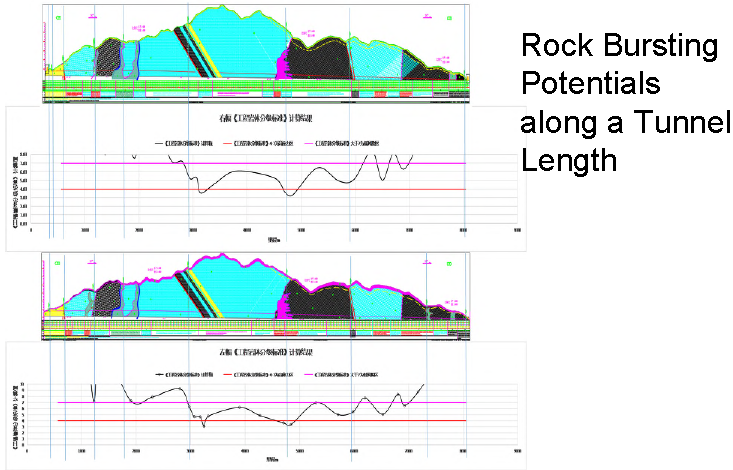

1. In-situ stress is an important design parameter for deep-buried tunnels.– Rock bursting and large deformation due to tunnel excavation

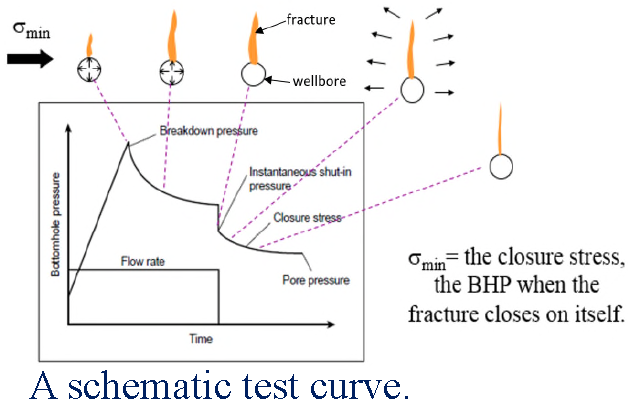

2. Mini-frac test is the most reliable method in measuring in-situ stress condition.

3. On the basis of our strength in serving the oil/gas sectors, has expanded our mini-frac (openhole) service to tunnel engineering.

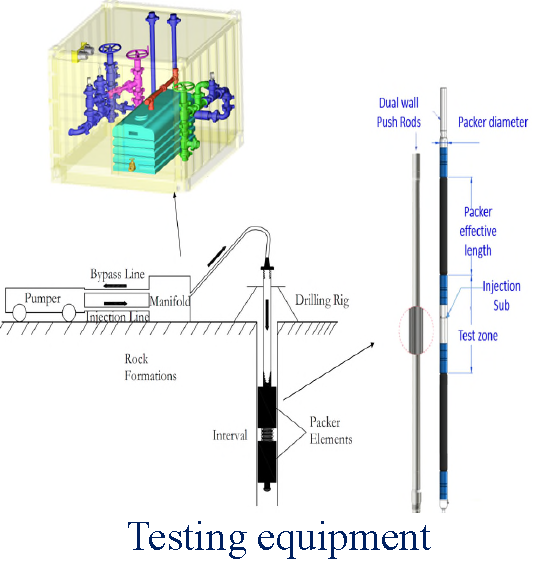

Testing Equipment

• Manifold system:– Maximum pressure: 35MPa

– Maximum flow rate: 50L/Min; Minimum flow rate: 3L/Min

– Fine-controlled injection, flowback and bypass system

• Light weight pump (up to 60 MPa)

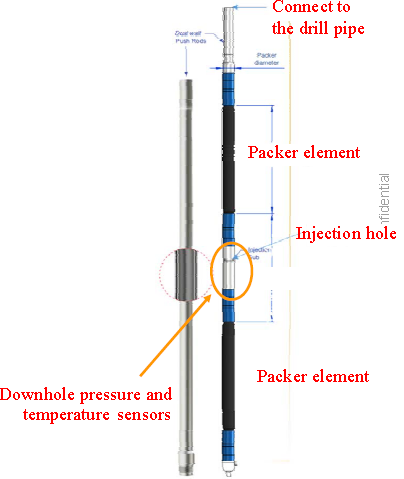

• Reusable downhole straddle packer:

– Maximum pressure: 85MPa(Diameter:33mm-190m)

– Testing interval: 0.5m-2.5m

– Equipped with downhole pressure and temperature sensors

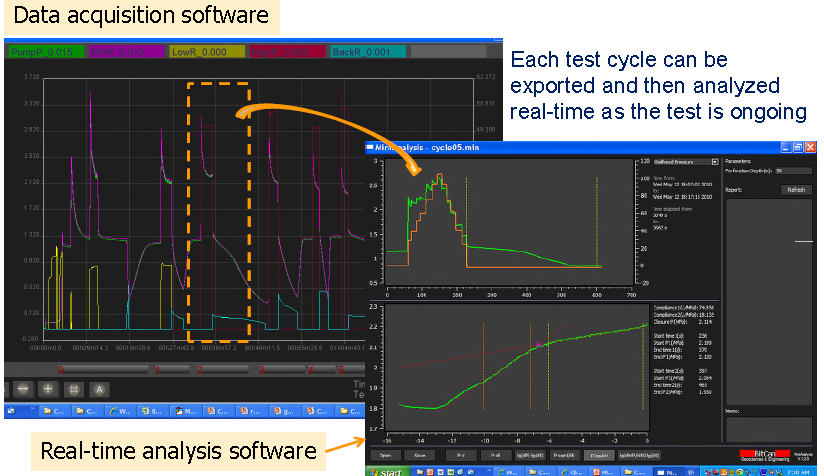

Real Time Analysis and Decision Software

Deliverables From a Mini Frac Test, Openhole

Three principal stress components:– Sv, Shmin and Shmax

– Direction of the principal stress (impression packer)

– Formation fluid properties, e.g., permeability

One Application of Mini Frac Test Results

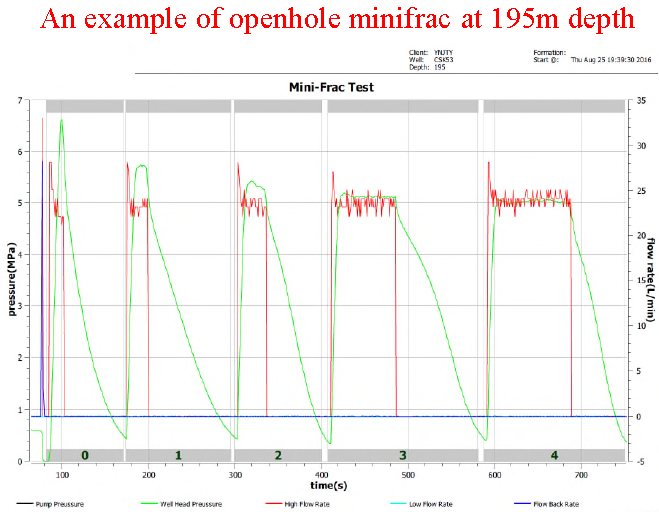

Some Example Test